Design for Manufacturing Services

Streamline Your Product Journey with DfM Solutions

Design Approach

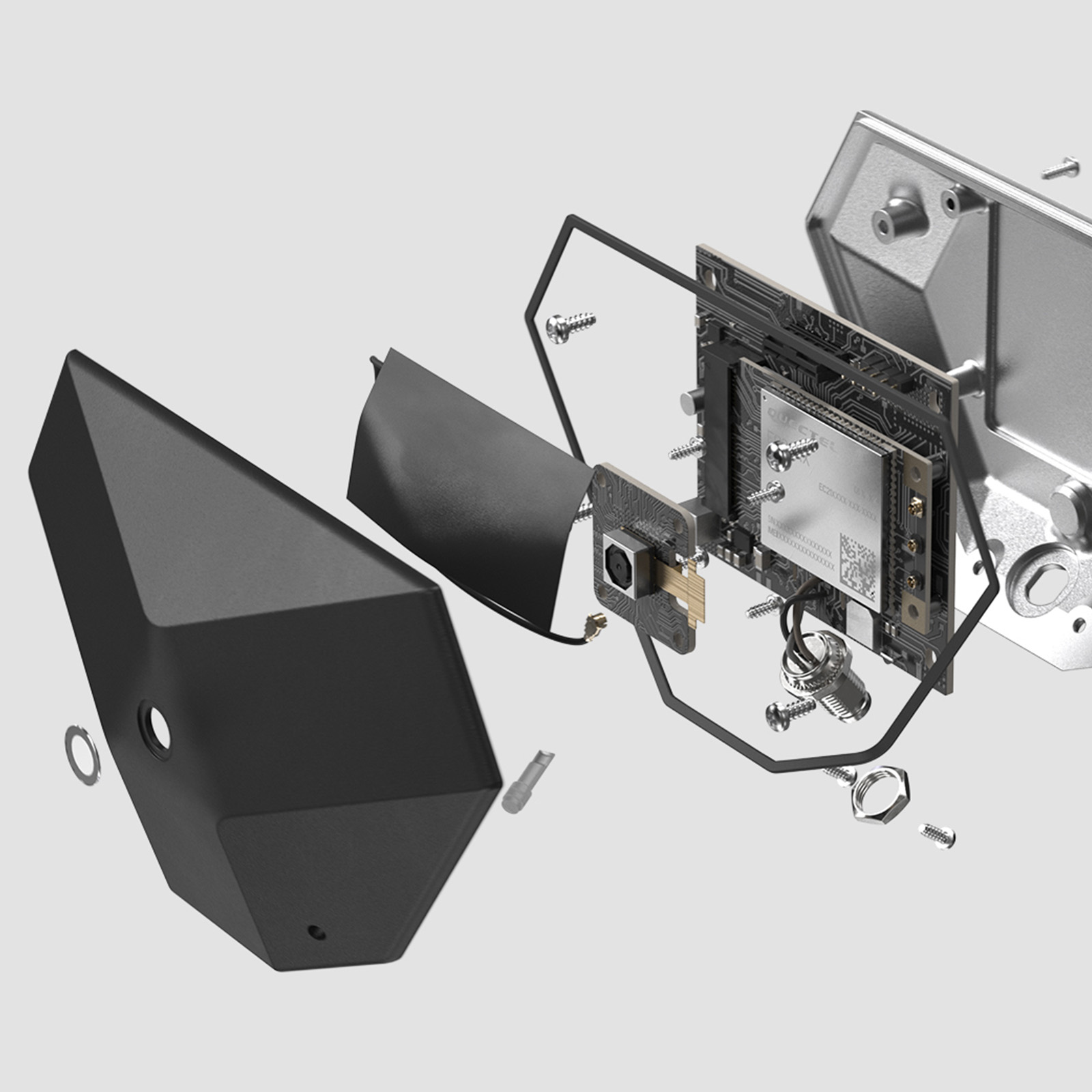

Bringing a product from concept to market requires more than just a great design. At Lesid, we specialize in design for manufacturing (DfM), ensuring that your product is not only functional and innovative but also cost-effective and production-ready. Our DfM solutions help businesses minimize risks, reduce production costs, and accelerate time-to-market without compromising design quality.

Why Choose Design for Manufacturing Solutions?

By addressing potential manufacturing issues early in the design phase, we reduce the need for costly modifications later. DfM is critical for bridging the gap between product design and large-scale production. By analyzing every aspect of the design and manufacturing process, Lesid ensures that your product is ready for full-scale manufacturing.

The Role of DFM Services

Collaborating closely with manufacturers allows us to produce high-fidelity prototypes that mirror the final product, emphasizing the importance of aesthetics and functionality in every detail. Lesid’s team provides comprehensive support, working closely with clients to refine designs, identify challenges, and implement solutions that enhance production efficiency.

Key Stages in Design for Manufacturing

Steps We Take

01

Initial Assessment and Feasibility Study

Every DfM project begins with a detailed assessment of your product design. Lesid evaluates the design’s feasibility for manufacturing, identifying potential challenges and opportunities for improvement.

02

Material Selection and Analysis

Choosing the right materials is crucial for balancing cost, durability, and performance. We research and analyze material options to recommend the best solutions for your product’s requirements and intended use.

03

Optimization for Manufacturing

Lesid refines your design to ensure it is production-ready. This includes simplifying complex features, optimizing assembly processes, and reducing material waste to improve manufacturability and cost efficiency.

04

Prototyping and Testing

Before full-scale production, we create prototypes to test the optimized design. This step allows us to validate the design’s performance and functionality while addressing any remaining issues.

05

Manufacturing Process Setup

We collaborate with manufacturers to develop efficient production processes. This includes analyzing final samples and making adjustments before moving to full-scale production.

06

Final Approval and Support

Once the desired result is achieved, we provide ongoing support during the production phase to ensure smooth manufacturing and address any unexpected challenges.

What are the Benefits?

Our Main Advantages

When it comes to optimizing your product for manufacturing, it’s essential to find creative solutions to solve technical problems while maintaining attention to detail and aesthetics. Here’s why we stand out:

- End-to-End Support

From design assessment to full-scale production, we provide comprehensive support to streamline the manufacturing process. - Cost-Effective Solutions

By identifying inefficiencies early, we help reduce production costs while maintaining product quality. - Custom-Tailored Approach

Every product is unique, and we adapt our methods to fit your specific goals and manufacturing requirements. - Proven Expertise

With years of experience, our team has a track record of delivering successful, production-ready designs across various industries. - Improved Product Quality

By addressing design and production challenges early, we ensure your final product meets the highest standards of quality and reliability.